Custom Machining, Fabrication, and Installation Services

For intricate or simple milling, lathing, drilling, welding, grinding, and sand blasting, our skilled technicians have the experience to perform the services needed for any size job. Licensed electricians, millwrights, mechanics, project managers, and machinists will make it happen with one source.

Sheet Metal Assembly

We use a powder coat method of painting in which we spray statically charged powder onto metal, then bake it in large ovens until cured. Powder paint is sold in almost any color and texture and the dry paint method is much cleaner than wet paint, eliminating problems like runs and drips.

Often our parts are shipped to the customer to be assembled into the final product. However, if a customer desires a more complete product when it arrives on their floor, we have the capability to perform electro-mechanical assembly at any level- from basic to complex. Finally, we can even perform product testing to ensure that the final assembly is working properly before it leaves our facility.

Get started on your next project!

- Electro-Mechanical Assembly

- Basic Assembly Operation

- Large Welded Frames

- Complex Bend and Weld

- Detailed Weld

- Customized Weld

Orders that may require additional processing time contain any of the following:

- Material over 3 inches thick or plate/sheet over 120 inches long

- Special order materials

In the rare instance where we require more than 24-hours to process and ship your order, we will contact you to let you know there is a delay.

What We Do

Darana Hybrid handles a variety of sheet metal fabrication projects. We work to your exacting standards to ensure a quality product.

We specialize in a number of services including:

- Complex sheet metal weldments

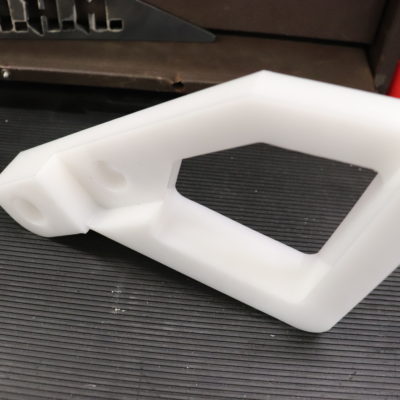

- Machined parts

- Cosmetic parts

- Complex forming

- Final assembly

- Sheet metal bending

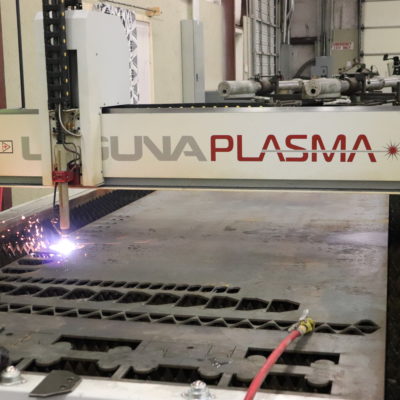

- Metal laser cutting

- MIG welding

- TIG welding

- CNC machining

Our team of experienced welders offer extensive fabrication options and can weld stainless steel, carbon, galvanized steel, aluminum, and copper. Additionally, this talented team of welders can fabricate structural steel, sheet metal, and even structural add-ons like mezzanines. And if the piece you need for a project cannot be fabricated on-site, Darana has a 24,000-square-foot, state-of-the-art fabrication facility designed to handle any need that arises.

Fabrication shop specifics:

- Cutting: 5-foot x 10-foot dual table plasma cutter. Mild steel – up to ¾ inch thick.

- Breaking: break capacity – up to 175-ton x 12-feet

- Shearing: shear capacity – up to 10-foot. x ¼ inch mild steel

- Rolling: plate roll capacity – up to 6 ft. x 3/16 inch

Items commonly fabricated:

- Crossovers and catwalks

- Machine bases and frames

- Fume hoods

- Mezzanines

- Work platforms

- Handrails/safety handrails

- Stairs

- General frames

- Belt and machine guards

- Chutes

- Hoppers

- Collectors

Dustless Blasting Services

Media Blasting Services:

- Removal of paint

- Primer

- Rust

- Sanitary surface preparation of stainless-steel fabrication’s

- Chloride leaving a perfect paint ready surface.

- Our process also prevents Flash Rust for up to 72 hours!

Using Various Media:

- #8 Glass Beads

- Soda

- Walnut shells

- Other media blasting

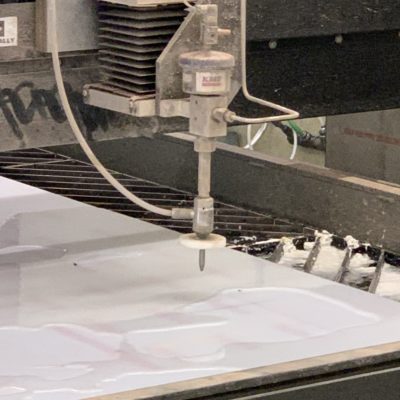

Waterjet Cutting Services

Provides many advantages including;

- Omni Directional Cutting

- A variety of waterjet materials

- Metal

- Stone

- Composites

- Glass

- Plastic

- Fiberglass